T HE advent of curved jaw crusher wearing plates - RocketCDN

Jaw Crusher Capacities, Blake and Single-Toggle generally have little effect on nip-angle if both jaw plates have flat areas.

Learn MoreCalculating the nip angle of the chamber of jaw and cone crushers with

Calculating the nip angle of the chamber of jaw and cone crushers with inclusion of the velocity vector A. D. Rudnev & V. D. Rudnev Soviet Mining 21 , 155-159 ( 1985) Cite this article 285 Accesses Metrics Download to read the full article text Literature Cited L. B. Levenson, "Fracturing theory and its application to jaw crushers", Zap. Leningr.

Learn MoreThread: Nip Angle and Its Use - bulk-online Forums

The nip angle describes the angle the stationary jaw plate and the pitman make with each other. The exact value of this angle isn't quoted or

Learn MoreNip Angle On Jaw Crusher In Algeria

Jaw crusher trio ct series primary weir. trio ct series jaw crushers combine a robust design with a steep nip angle and an optimised toggle. this results in a jaw crusher which offers a aggressive bite and reliable operation, with life-cycle improvements of its mechanical and hydraulic parts.

Learn Morewhat is jaw crusher neep angle

Double roll crusher nip angle illite caesar heavy jaw crusher neep angle libranhjaw crusher neep angle nip angle in jaw angle in a jaw crusher19 apr 49 if a is the angle of nip between the crusher jaws and lt and lmax are the throw and open side setting respectively then tana or h more details jaw crusher nip angle the nip angleget price.

Learn MoreJAW CRUSHER SERIES - Mining

Jaw crushers are normally capable of a reduction ratio of 1:2 or 1:3. This ratio is affected by the feed material’s bulk density, crushability, size distribution and moisture content – among other

Learn Moreangle of nip in roll crusher

Angle Of Nip For Jaw And Roll Crusher. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related you are interested in our products

Learn MoreAMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Angle of nip varies for large crusher between 21 °to 24 °. For curved surfaces, the nip varies from 27 ° to 30 °. The distances between the concave surface and

Learn MorePDF JAW CRUSHER SERIES - Mining and Rock TechnologyPDF

The nip angle is the angle between the fixed and moving jaw plates. Our CJ crushers have an optimum nip angle in the 16-23 degree range. Product picture to be placed here.

Learn MoreJaw Resources | MPS

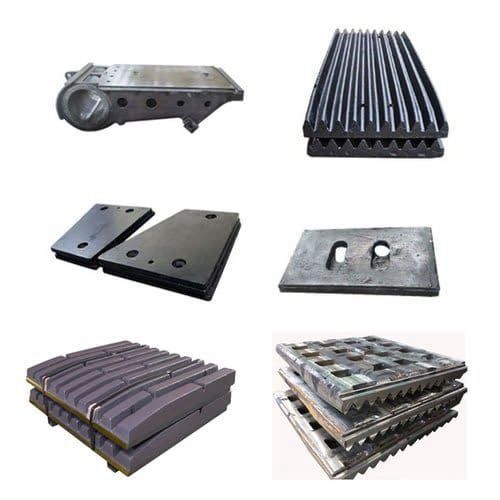

Minimum distance between jaw die derived from the OSS and the stroke. Nip Angle Inclusive angle between jaw die indicative of the crusher’s ability to crush and draw rock. Fixed Jaw Replaceable die attached to the fixed frame. Swing Jaw Replaceable die plate attached to the pitman. Cheek Plates Bolt on wear plates designed to protect crusher frame.

Learn MoreJaw Crusher Power Consumption And Nip Angle Effect

Crusher Close Side Settings - Mineral Processing & Metallurgy. Nip angle The nip angle is the angle between the fixed and movable jaw dies. Too large a nip angle reduces the capacity and increases the wear as the feed material grinds and gouges the jaw dies in an upwards direction during the compressive stroke of the pitman.

Learn More

Leave A Reply