What is a Jaw Crusher? - MEKA Crushing Equipment

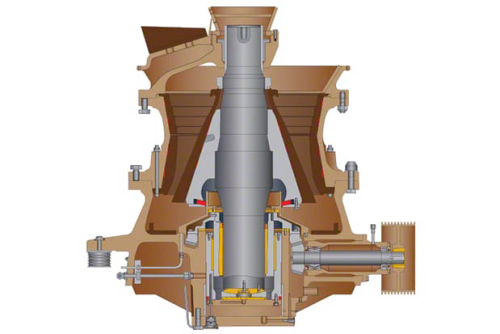

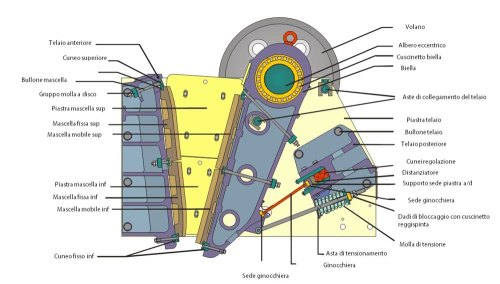

WHAT IS A JAW CRUSHER? / JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes. It is usually preferred for the crushing of large blocks of hard and abrasive materials. HOW DO JAW CRUSHERS WORK? / THE WORKING PRINCIPLE OF JAW CRUSHERS

Learn MoreJaw Crusher - ScienceDirect

This mathematical concept of jaw crusher operation has been developed for modelling and subsequent throughput prediction from jaw crushers (see Chapter 10). 4.4. Jaw Crusher Capacity Estimation. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation.

Learn MoreWhat is the best material for crusher jaw plates?

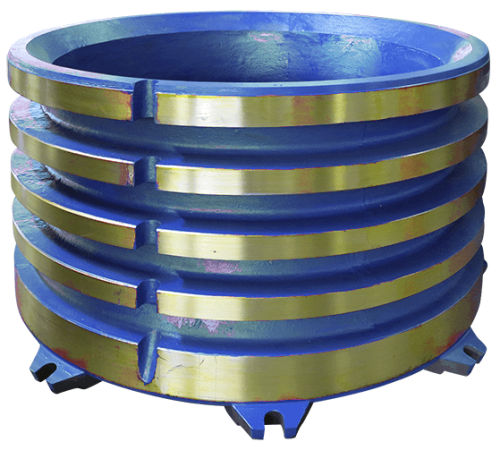

Mn18Cr2 is the most popular material for casting jaw crusher jaw plates. This Mn18Cr2 jaw plates widely in crushing difficult and non-abrasive blasted rock, medium and non-abrasive,non-abrasive gravel, and non-abrasive round rock. Mn22Cr2 Jaw Plates. Mn22Cr2 jaw plates are widely used in crushing hard and abrasive stones.

Learn MoreJaw Crusher For Sale | Jaw Crusher | Jaw Crusher Manufacturer

The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa. Widely apply for mining, cement and concrete industries. It is mainly used as coarse crusher and medium crusher in mines, building materials and infrastructure. The jaw cement crusher produced by AGICO Cement has the characteristics of simple structure, easy

Learn MoreMaterial For Jaw Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Crushing materials: Jaw crusher can crush granite, black trap, basalt, river gravel, bauxite, marble, slag, hard rock, limestone, coal, iron ore, magazine ore and so on. Jaw crushers,Primary jaw crusher,Jaw breaker,Stone crusher In industry, China jaw crushers are machines which use a metal surface to break or compress materials.

Learn MoreWhat is TMJ Disorder - Hillsboro Dental Excellence

Many patients find that administering Botox in the muscles around the TMJ relieves pain and stiffness in the jaw. Custom Splints and Bite Guards . If your TMD is a result of teeth grinding, teeth clenching, or muscle spasms, a custom made splint or bite guard can take pressure off your joints.

Learn MoreHow to Select the Right Jaw Crusher - Gilson Company

Many of these materials are hard, tough, or brittle, so crushing them to smaller sizes is an ideal application for robust, rugged, and durable jaw crushers.

Learn MoreHow does a Rock Crusher Work - Jaw Crusher - 911 Metallurgist

A jaw crusher is recommended for tough, abrasive, high compressive strength materials. Special machines have been designed for ores having

Learn MoreAggregate Crushers - High-efficiency And Eco-friendly

Next, let me introduce to you the aggregate crusher types. Jaw Aggregate Crushers - Large Feeding Port For Crushing Large Materials. Aggregate jaw crusher is mainly used for processing bulk material. Its maximum feed size can reach 1200mm*1600mm, which can meet the needs of processing large pieces of construction waste aggregate.

Learn MoreWhat is Jaw Crusher? - EVORTLE

Jaw crushers are mainly the primary stage of material reduction in aggregate processing plants. As a compression type crusher, jaw crusher is comprised of a

Learn MoreJaw Crushers - high quality and reliability from RETSCH

Jaw Crushers for efficient primary size reduction ; BB 250. Jaw Crusher BB 250. Material feed size*: < 120 x 90 mm ; BB 400. Jaw Crusher BB 400. Material feed

Learn More

Leave A Reply