Choosing the Right Rock Crushing Equipment - Amcast

A jaw crusher also uses compressive force and the materials are allowed into a gap at the top of the equipment between two jaws. One of the jaws

Learn MoreTypes of Crushing Equipment - Jaw, Cone & Impact

It's a primary crusher. The jaw crusher is a machine for crushing rocks and other hard and abrasive materials, such as granite, ores or recycled concrete,

Learn MorePatriot® Cone Crusher | Secondary or Tertiary Crusher | Superior Industries

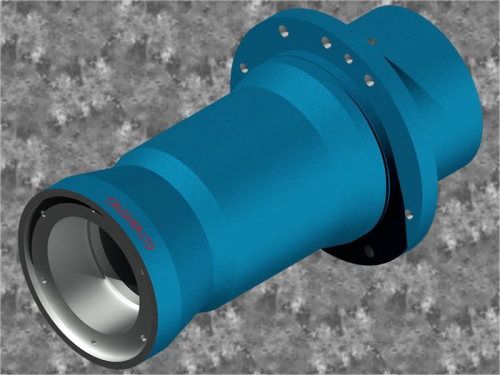

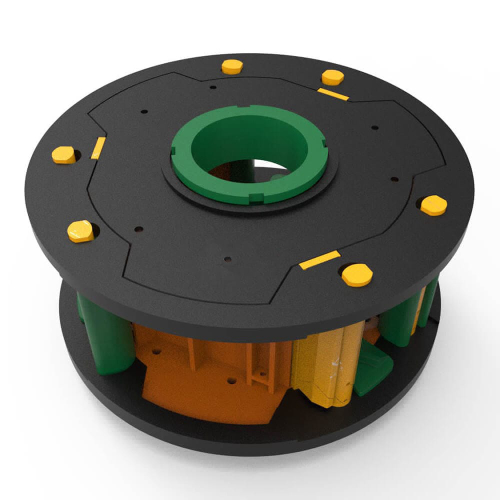

As rock is compressed between the mantle and the bowl, the force generated fractures the material. This process continues until the pieces are small enough to fall through the bottom. Superior manufactures several cone models: Maximum feed size up to 12 7/16″ (316mm) Final product size of 5″ - minus #6 (125mm - 3mm)

Learn MoreCH440 Cone crusher - Mining and Rock Technology

CH440 cone crusher offers full control of the process. When CH440 cone crusher is equipped with our automatic setting system, it automatically adapts the crusher to variations in feed conditions. By continuously measuring and compensating for crusher liner wear, the automation system allows you to fully utilize crusher liners

Learn MoreCone Crusher for Rent Alberta & British Columbia - Mormak

Call Mormak so our experts can guide you through our selection of new cone & rock crushing machines & aggregate equipment sales. CONE CRUSHERS FOR SALE AND

Learn MoreCone Crushers - Astec

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market. Crushing.

Learn MoreCone crusher basics in 4 minutes — SRP

This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information

Learn More12 tips to maximize cone crusher productivity - Outotec

2/11 · Avoid trickle feeding the crusher. Try not to trickle feed a cone crusher. In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher. A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to

Learn MoreHigh Quality Productivity Mini Rock Stone Cone Crusher Hot Sale Mining

High Quality Productivity Mini Rock Stone Cone Crusher Hot Sale Mining Stone Cone Crusher , Find Complete Details about High Quality Productivity Mini Rock Stone Cone Crusher Hot Sale Mining Stone Cone Crusher,Cone Crusher Machine Plant Cone Crusher Equipment,Horizontal Bar Hydraulic Cone Crusher Factory Direct Sales,Hot Ore Crusher Cone Crusher Crusher Spare Parts from Crusher Supplier or

Learn MoreCone Crusher, Cone Crusher,Hydraulic Cone Crusher,Rock Cone

General Idea of the Cone Crusher. Cone crusher is used for crushing all kinds of ores and rocks with medium hardness or above-medium hardness in many industries, such as metallurgy, construction, road, chemical and silicate industries. It is very suitable for intermediate crushing and fine crushing of ores and rocks. There are by and large three types of cone crusher: cone crusher

Learn MoreCone Crushers - Sandrock Mining

Machine Type: SR200, SR300,SR400,SR600,SR800. Cone crushers are a type of compression crusher used by aggregate, coal, concrete, crushing, fracking sand, and mining industries, which reduces material by squeezing or compressing it until it breaks. Features. Superior Reliability. By continuously optimization and innovation, we focus on improving

Learn More

Leave A Reply