Safety Regulation of Jaw Crusher - Luoyang Dahua

Safety Regulation of Jaw Crusher author:dahua time:2019-11-19 Jaw crusher is the common used stone crusher machine in mining industry. It has the features of simple structure, stable

Learn MoreHSE - Quarries - Safe operation and use of mobile jaw crushers

The crusher should be shut off and isolated before considering the use of bars and hand hammers. Careful consideration should be given to the risk of large pieces of feed material moving and

Learn MoreImproving jaw crusher safety | Dry Bulk

05/06/ · Improving jaw crusher safety. According to the Health and Safety Executive’s guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple risks including exposure to dust, noise, whole body vibration and being struck by objects ejected from the crusher. Here is how, WEG’s main distributor

Learn MoreJaw Crushers | McLanahan

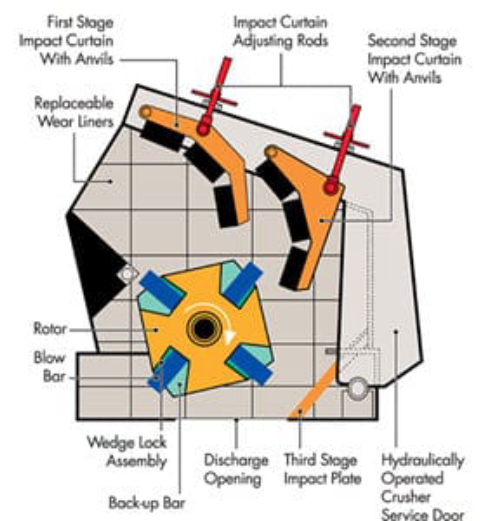

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

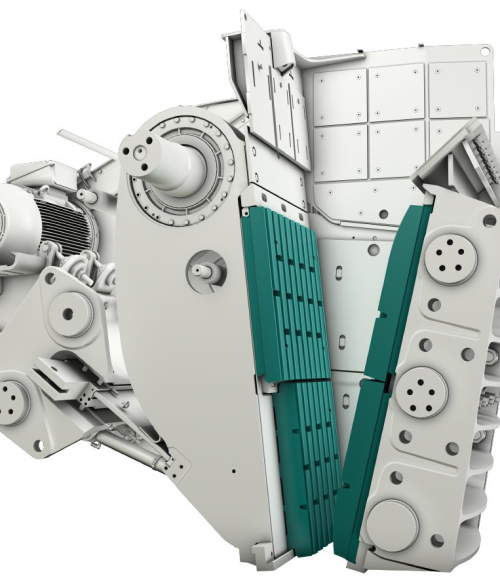

Learn MoreJaw crushers, Stationary Jaw crusher series — SRP

jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are delivered with everything you need for plug-and-play installation and safety features to keep operators out of danger. Backed up with a complete Reliability and Protection package, they get

Learn MoreJaw Crushers - high quality and reliability from RETSCH

The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants.

Learn Moremobile jaw crusher | leser safety valve

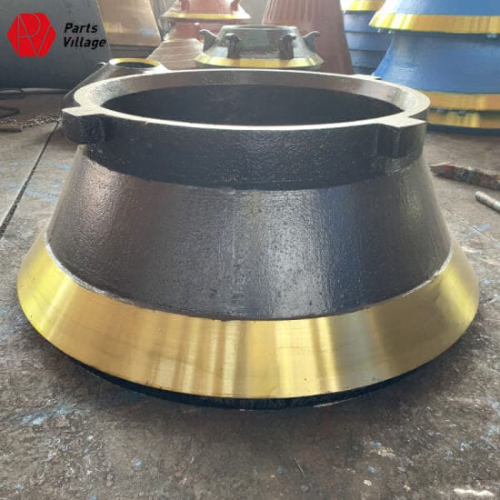

Cones, Jaw, Jaw Crusher, Jaw Crushers. Mobile Jaw Crusher Closed Side Setting (CSS) range. Figure 3 above: Taken from Training JAW-ST. Tips. Use the jaw crusher reverse function on the display screen to get the arrow on the flywheel in the correct position. Always measure the CSS with the arrow on the flywheel

Learn MoreSafe and sound: Crusher safety : Pit & Quarry

14/07/ · Safe and sound: Crusher safety. By Kevin Yanik | July 14, . A rock the size of a dining room table is plugged in the jaw crusher. After assessing the situation, a few people decide to wrap a chain around the rock and lift it out with a wheel loader. After securing the chain around the rock in the crushing chamber, a man still in the chamber

Learn MoreImproving jaw crusher safety | Global Mining Review

Improving jaw crusher safety. According to the Health and Safety Executive's guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple risks including exposure to dust, noise, whole body vibration and being struck by objects ejected from the crusher. Here is how, WEG's main distributor

Learn MoreWEG products help improve jaw crusher safety | Agg-Net

05/06/ · Technidrive use WEG equipment to create innovative jaw crusher unblocking system. Technidrive were not only able to improve the efficiency and reliability of the motor, but also the efficiency and safety of the entire jaw crusher system. With more than 20 years’ experience in industrial drives, they used all their expertise to meet the

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 45.7/0.85 = 53.6 cm and for a shape factor of 1.7, the width should be = 45.7 × 1.7 = 78 cm.

Learn More

Leave A Reply