jaw crusher working

together with the "client-oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy r&d staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for jaw crusher working, portable jaw crusher , vertical vibrator motor , bucket elevator ne plate ,

Learn MoreJaw Crusher Working Principle - m.gravelmill.com

Jaw Crusher Working Principle. Jaw crusher is widely used in industrial and mining enterprises , this is because the aircraft structure is relatively simple , and has a large range of models . Jaw crusher is mainly used as the primary crusher. It can be used with mineral processing equipment , gravel ancillary equipment, it also can be used alone.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

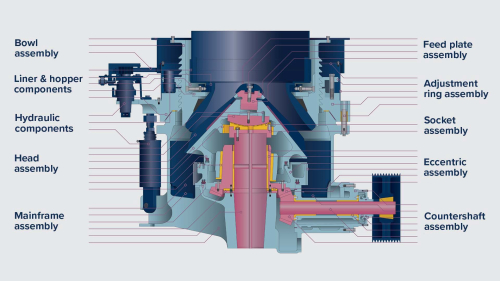

Although the main crushing process is complemented by jaw plates, the crucial parts that give a motion to the moveable jaw plate are toggle plate, pitman bearing and flywheel. The pitman drives the moveable jaw dies to push stone material towards stationary jaws, which would create strong pressing forces to both jaw dies.

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

The mechanism of movement of rocks down the crusher chamber determines the capacity of jaw crushers. The movement can be visualised as a succession of wedges (

Learn MoreWhat Are Jaw Crushers? & How Do They Work? - iBusiness Angel

Aug 05, · How Does A Jaw Crusher Work? Jaw crushers utilize mechanical pressure to apply compressive forces to reduce the size of larger rocks. Its structure is like that it has two crushing jaws. One jaw is movable while the other can’t move. These jaws work together to crush the materials by applying mechanical pressure.

Learn MoreHow Does a Jaw Crusher Work - Kemper Equipment

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary

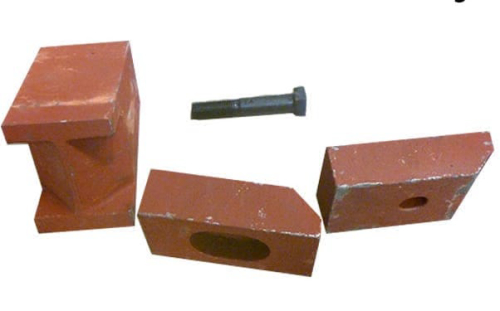

Learn Morejaw crusher toggle plate | crusher copper bush for sale

Jaw Crusher Wear Parts - Columbia Steel Casting Co., Inc. The right jaw design can make a big difference for your jaw crusher. Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the application. We have many case histories in which wear life increases of 50% are common, and some in which wear

Learn MoreJaw Crusher Working Principle - How Does It Work

A jaw crusher crushes large blocks of stone and abrasive materials. The stones go through a primary and secondary crushing process. Jaw crushers have two jaws: one remains fixed while the other one moves. The jaw crusher working principle works on the reciprocating movement of the movable jaw. This part crushes and compresses ores and Continue reading Jaw Crusher Working Principle - How

Learn MoreJaw crusher working principle and characteristics

Feb 17, · Jaw crusher works When the jaw crusher is working, the movable jaws make periodic reciprocating motions to the fixed jaws, sometimes approaching and sometimes leaving. When approaching, the material is crushed, split, and impacted between the jaws; when it is removed, the broken material is discharged from the discharge opening by gravity.

Learn MoreJaw Crusher Working Principle - Conmix Crusher

Crushing is done between the two crushing jaws. The moving jaw of the single toggle jaw crusher moves elliptically. A pendulum motion is being carried out by the double toggle jaw crusher. The crushing force is produced by an eccentric shaft. Then it is transferred to the crushing zone via a toggle plate system and supported by the back wall of

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

The jaw crusher consists of a fixed jaw plate which is mounted within the crusher mainframe and a movable jaw plate which is mounted to a jawstock.

Learn More

Leave A Reply