crusher jaws | crushers

Crusher jaws Incorporated in 1992, Chongqing Huade Machine Manufacturing Co.,Ltd have 3 factories with 505 workers with a production capability of 1200mtons per month. An individual piece casting of weight from 10 kg to 11000 kg,including high manganese,high Chromium,carbon steel and bronze steel crusher spar

Learn MorePE 600X900 Limestone/Coal/Basalt/Granite/ Jaw Crusher for Sale

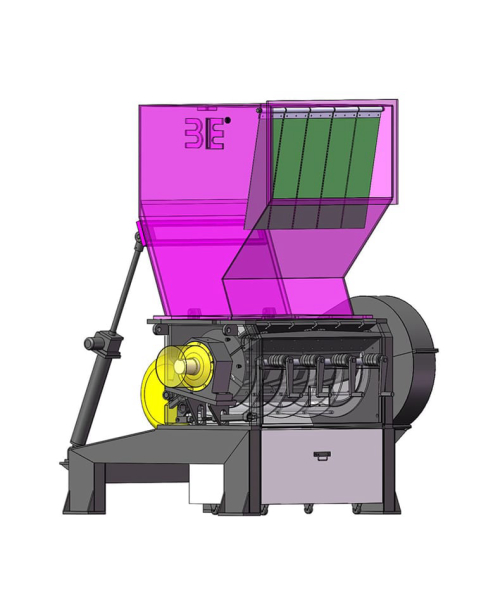

Jaw Crusher Machine Working Principle. When Jaw crusher working, motor through the pulley drive the eccentric shaft rotation, from the period of hubei near, fixed jaw, and for the material such as extrusion, rolling and run multiple broken, make material from large to small, gradually whereabouts until discharge through the discharge port.

Learn MoreSamscreen's Replacement Jaws for Crusher Machines

If you need a replacement jaw for your crushing machine that can withstand the toughest conditions, then you need Samscreen's Maxwear™ manganese jaws. Our replacement jaws feature Maxwear™ manganese in three grades depending on the crushing conditions encountered - 14 percent, 18-19 percent, and 21-23 percent. Samscreen's replacement jaws offer excellent wear life and fit and go through a rigorous quality control process.

Learn MoreNew & Used Jaw Crushers for sale - GrinderCrusherScreen

New & Used Jaw Crushers for rock, brick, concrete, and more in top brands such as Evortle, Extec, , Red Rhino, KPI, Komplet, and More. From Small/Mini Jaw Crushers to Large Jaw Crushers. Select Language

Learn MoreCrusher jaws Manufacturers & Suppliers, China crusher jaws

crusher jaws manufacturers/supplier, China crusher jaws manufacturer & factory list, find best price in Chinese crusher jaws manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com.

Learn MoreJaw crushers by SIEBTECHNIK TEMA. Crushing & milling

Jaw crushers are used for coarse grinding brittle, medium-hard to hard materials up to a Mohs' hardness of approx. 8.5. Here reduction ratios of up to 1:100

Learn MoreJaw Crushers | McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern

Learn MoreJaw Crusher For Sale | Jaw Crusher | Jaw Crusher Manufacturer

Jaw crusher for sale. Production Capacity: 1-1200 t/h. Feeding Size: 125-1200 mm. Application: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc. . The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa. Widely

Learn MoreHow Does a Jaw Crusher Work - Kemper Equipment

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary

Learn MoreStationary jaw crushers - rockprocessing

jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

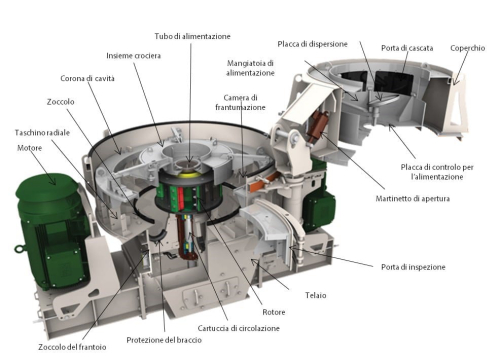

Jaw crushers . Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce the material to a small enough size that it can be transported by conveyors to the next crushing stages. As the name suggest, jaw crushers reduce rock and other materials between a fixed and a moving jaw.

Learn More

Leave A Reply