Jaw Crushers - PR Engineering

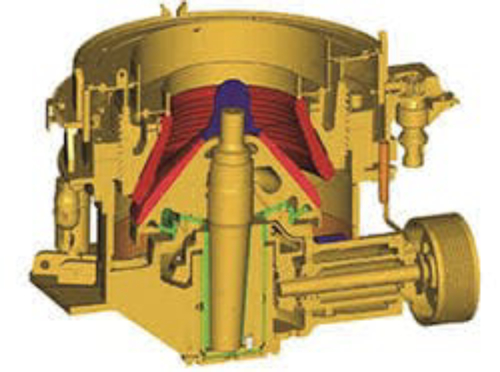

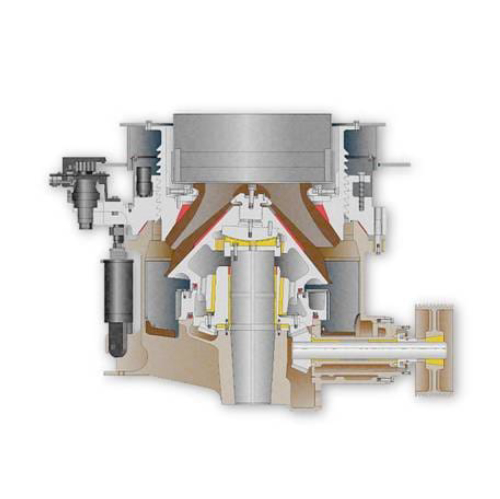

Over the years, the design of the jaw crusher has proven to be much more effective when tough, hard and/or abrasive crushing is needed. Our Double Toggle Crusher is more suitable for a hard-rock application and is preferred in certain situations over a single toggle crusher due to wear and tear, and the increased downtime for servicing.

Learn MoreJaw crushers - Thyssen Krupp

crusher, which differ in the kinematics of the swing jaw: single-toggle jaw crushers for a high throughput rate and double- toggle jaw crushers for

Learn MoreDouble Toggle Jaw Crusher, Stone Crusher Manufacturer - Royal Engineering

Our Jaw Crushers are configured for Primary & Secondary crushing of even hardest rock at hardest speed with minimum power. The crusher is designed on principal of Crushing without Rub with high impact pressure. Our Jaw Crushers are considerably higher than that of conventional crushers, without rub & requires minimum dust oil lubrication.

Learn MoreSingle Toggle vs Double Toggle Jaw Crusher

The double toggle jaw crusher has two forms of working direction: one is a swing motion toward the fixed die plate, and the other is a vertical

Learn MoreSingle toggle Jaw Crusher vs Double Toggle Jaw Crusher

2/8 · Jaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Toggle. In the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving jaw which is pivoted at

Learn MoreJaw Crusher, Double Toggle Jaw Crushers, Single Toggle Jaw Crushers

Double Toggle Jaw Crushers are preferred for crushing ususually hard, abrasive rocks and other materials like ferroalloys and glass. They differ substantially from other types of crushers. There is no rotary motion in the crushing cycle and all crushing is done by compression of the feed material between two massive jaws plates.

Learn MoreJaw Stone Crusher | Single Toggle vs Double Toggle

The movement track of each point on moving jaw is more complex in this kind of machine, so it is called a double toggle jaw crusher. Compared with the single toggle jaw stone crusher, the

Learn Moredouble vs single toggle jaw crusher

Difference Between Single & Double Toggle Jaw 2014-9-20 A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than

Learn MoreSingle toggle Jaw Crusher vs Double Toggle Jaw

2/8 · Jaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Toggle. In the double toggle crusher the rotation of an

Learn MoreDouble Toggle Jaw Crusher

Industry Encyclopedia】 Jaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Toggle. In the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving jaw which is pivoted at its upper edge.

Learn MoreX KUE KEN DOUBLE TOGGLE JAW CRUSHER - Just Recycling

KUE KEN DOUBLE TOGGLE JAW CRUSHER DATA: Make: KUE KEN. Model: 42 x 14 double toggle jaw crusher. Motor: N/A. Jaw Size: 42 inches x 14 inches. Additional information. Dimensions. 100 × 70 × 170 cm. Brand.

Learn More

Leave A Reply